推荐消息更多>>

推荐消息更多>>想了解气力输送系统的工业物料传输的得力助手吗?

- 来源:https://www.sdxinlujx.com/ 日期:2025-03-17 发布人:创始人

在现代工业生产中,高效、稳定的物料输送至关重要。气力输送系统作为一种先进的物料输送方式,正广泛应用于各个行业,为工业生产的顺畅运行提供了有力支持。

Efficient and stable material transportation is crucial in modern industrial production. As an advanced material conveying method, pneumatic conveying system is widely used in various industries, providing strong support for the smooth operation of industrial production.

工作原理探秘

Exploring the working principle

气力输送系统主要依靠气体的流动来推动物料在管道中移动。其基本原理是利用风机或压缩机产生具有一定压力和流速的气流,将物料混入其中,在气流的携带下,物料通过管道被输送到指定地点。根据物料特性和输送要求的不同,气力输送可分为稀相输送和密相输送。

The pneumatic conveying system mainly relies on the flow of gas to move materials in the pipeline. The basic principle is to use a fan or compressor to generate an airflow with a certain pressure and flow rate, mix the material into it, and transport it to a designated location through pipelines under the carrying of the airflow. According to different material characteristics and conveying requirements, pneumatic conveying can be divided into dilute phase conveying and dense phase conveying.

稀相输送时,物料在气流中呈悬浮状态,气固混合比相对较低,一般在 10 以下。这种输送方式适用于颗粒较小、流动性较好的物料,输送速度较高,通常在 15 - 30m/s。由于物料在管道内处于悬浮状态,与管道壁的摩擦相对较小,能够实现长距离输送。

During dilute phase transportation, the material is suspended in the airflow, and the gas-solid mixing ratio is relatively low, generally below 10. This conveying method is suitable for materials with small particles and good flowability, with a high conveying speed, usually between 15-30m/s. Due to the suspended state of the material inside the pipeline, the friction with the pipeline wall is relatively small, enabling long-distance transportation.

密相输送则适用于一些对输送过程要求较高、易破碎或磨蚀性较强的物料。在密相输送中,物料以较低的速度、较高的浓度在管道中流动,气固混合比可高达 50 以上。密相输送又可细分为栓流密相输送和流化密相输送。栓流密相输送通过将物料分割成一段段料栓,利用气体压力推动料栓前进;流化密相输送则是通过特殊的供气装置使物料在管道内呈流化状态,在气流作用下平稳输送。

Dense phase conveying is suitable for materials that have high requirements for the conveying process, are prone to breakage or have strong abrasion. In dense phase transportation, materials flow in pipelines at lower speeds and higher concentrations, and the gas-solid mixture ratio can reach over 50. Dense phase transportation can be further divided into plug flow dense phase transportation and fluidized dense phase transportation. Plug flow dense phase transportation divides materials into sections of plugs and uses gas pressure to push the plugs forward; Fluidized dense phase transportation is achieved by using a special gas supply device to make the material in a fluidized state inside the pipeline, and smoothly transported under the action of airflow.

多样的系统类型

Diverse system types

根据气源的不同,气力输送系统可分为吸送式和压送式。吸送式气力输送系统利用真空泵在管道内形成负压,使物料随外界空气一起被吸入管道,再输送至卸料点。这种方式适用于从多个供料点向一个卸料点输送物料的情况,如在粮食加工行业中,可从不同的粮仓向加工车间输送谷物。其优点是能在输送过程中对物料进行初步的筛分和除尘,且供料装置相对简单。

According to the different gas sources, pneumatic conveying systems can be divided into suction type and pressure type. The suction pneumatic conveying system uses a vacuum pump to create negative pressure inside the pipeline, causing the material to be sucked into the pipeline along with the outside air and then transported to the discharge point. This method is suitable for conveying materials from multiple feeding points to one unloading point, such as in the grain processing industry, where grains can be transported from different silos to the processing workshop. Its advantage is that it can perform preliminary screening and dust removal on materials during the conveying process, and the feeding device is relatively simple.

压送式气力输送系统则依靠空压机等设备向管道内输入高压气体,将物料从供料点压送至卸料点。它适用于从一个供料点向多个卸料点输送物料的场合,在化工生产中,常用来将原料输送到不同的反应装置。压送式气力输送系统输送能力较大,输送距离更远,且可在正压环境下进行输送,避免了外界杂质的混入。

The pressure feeding pneumatic conveying system relies on equipment such as air compressors to input high-pressure gas into the pipeline, and pressurizes the material from the feeding point to the unloading point. It is suitable for conveying materials from one feeding point to multiple unloading points. In chemical production, it is commonly used to transport raw materials to different reaction devices. The pressure pneumatic conveying system has a large conveying capacity, longer conveying distance, and can be conveyed in a positive pressure environment, avoiding the mixing of external impurities.

本文由气力输送系统友情奉献.更多有关的知识请点击:https://www.sdxinlujx.com真诚的态度.为您提供为全面的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from the pneumatic conveying system For more information, please click on: Sincere Attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Coming soon.

- 上一篇: 气力输送系统:高效物料输送的关键力量

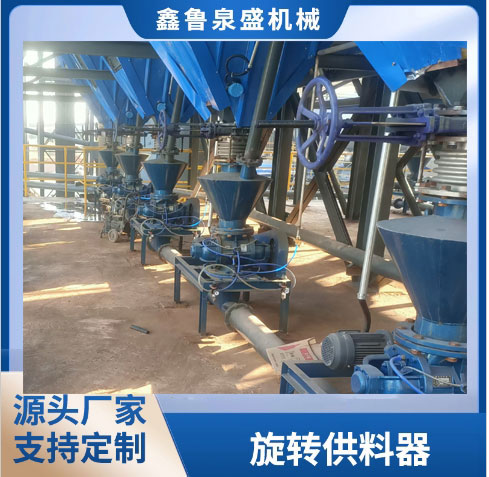

- 下一篇: 旋转供料器是怎么成为工业生产的物料输送枢纽的呢?

扫码微信沟通

扫码微信沟通