推荐消息更多>>

推荐消息更多>>旋转供料器在气力输送系统中的重要作用

- 来源:https://www.sdxinlujx.com/ 日期:2024-12-10 发布人:创始人

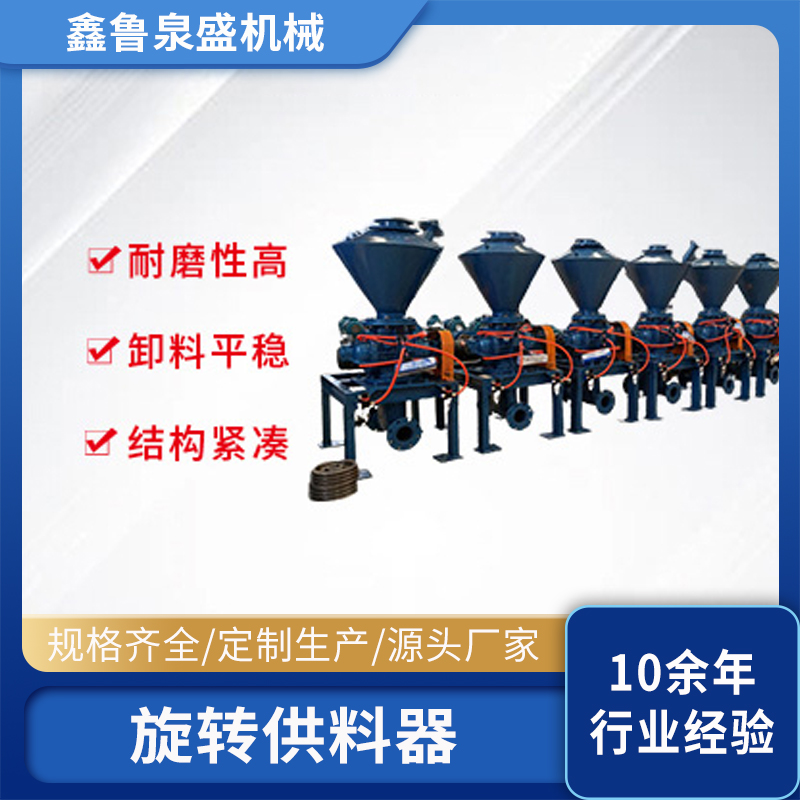

旋转供料器是一种用于固体物料输送系统的设备,广泛应用于气力输送系统中。它通过旋转叶片将物料从上部料斗卸出并均匀喂入下一装置,适用于粉状和颗粒状物料的定量给料。

Rotary feeder is a device used in solid material conveying systems, widely used in pneumatic conveying systems. It unloads materials from the upper hopper and evenly feeds them into the next device by rotating blades, suitable for quantitative feeding of powdered and granular materials.

旋转供料器的结构通常包括转子、壳体、端盖、电机和减速机等部分。转子由多个叶片组成,可以在圆筒形机壳内旋转,物料从上部料斗落入后填充在叶片间的空隙中,随叶片旋转至下部而卸出。机体侧面设有均压排气口,可以排出高压气体,减少气体顶料现象,有利于物料的顺利下落。

The structure of a rotary feeder usually includes parts such as rotor, housing, end cover, motor, and reducer. The rotor is composed of multiple blades and can rotate inside a cylindrical casing. The material falls from the upper hopper and fills the gaps between the blades, and is discharged as the blades rotate to the lower part. There is a pressure equalization exhaust port on the side of the body, which can discharge high-pressure gas, reduce the phenomenon of gas topping, and facilitate the smooth falling of materials.

旋转供料器在气力输送系统中扮演着重要角色,能够均匀而连续地向管道内供料,并在系统的分离和收尘部分具备卸料器和锁气器的功能。其设计特点包括结构紧凑、密封性能好、给料均匀、运行可靠等优点,适用于粉状物料和颗粒状物料的输送。

Rotary feeders play an important role in pneumatic conveying systems, capable of uniformly and continuously feeding into pipelines, and have the functions of unloaders and air locks in the separation and dust collection parts of the system. Its design features include compact structure, good sealing performance, uniform feeding, and reliable operation, making it suitable for conveying powdered and granular materials.

旋转供料器的应用范围非常广泛,包括粮食加工、化工原料、塑料冶金、能源矿业、建材水泥等行业,以及啤酒厂麦芽车间、酿造车间等场所。此外,它还被用于除尘设备排灰、送风和其他设备的给料装置中。

The application range of rotary feeders is very wide, including industries such as grain processing, chemical raw materials, plastic metallurgy, energy mining, building materials and cement, as well as places such as malt workshops and brewing workshops in breweries. In addition, it is also used in the feeding devices of dust removal equipment, air supply, and other equipment.

在使用过程中,旋转供料器需要特别注意防止粉尘卡住灰斗或刚性物料,以避免损坏设备和加速磨损叶轮。同时,为了确保设备的正常运行,需要定期检查和维护,如补充或更换润滑油和润滑脂,特别是在高温环境下应缩短换油时间。

During use, special attention should be paid to preventing dust from getting stuck in the ash hopper or rigid materials, in order to avoid damaging the equipment and accelerating the wear of the impeller. At the same time, in order to ensure the normal operation of the equipment, regular inspections and maintenance are necessary, such as supplementing or replacing lubricating oil and grease, especially in high-temperature environments where the oil change time should be shortened.

旋转供料器的设计和选型对于确保系统的性能至关重要。根据物料的性质、输送量及作用力合理选择尺寸、结构和转速,可以有效提高设备的使用寿命和工作效率。此外,旋转供料器的耐磨性和密封性也是其重要特性之一,通过采用弹性转子设计,可以更好地保证均匀喂料。

The design and selection of rotary feeders are crucial for ensuring the performance of the system. Reasonably selecting size, structure, and speed based on the properties, conveying capacity, and force of the material can effectively improve the service life and work efficiency of the equipment. In addition, the wear resistance and sealing performance of the rotary feeder are also important characteristics. By adopting an elastic rotor design, uniform feeding can be better ensured.

旋转供料器在现代工业生产中发挥着重要作用,特别是在气力输送系统中,其独特的防卡装置设计确保了物料的均匀喂料,从而提高了系统的效率和经济效益。

Rotary feeders play an important role in modern industrial production, especially in pneumatic conveying systems. Their unique anti jamming device design ensures uniform feeding of materials, thereby improving the efficiency and economic benefits of the system.

本文由旋转供料器为您提供,我们的网站是:https://www.sdxinlujx.com我们将以全心全意的热情为您提供服务,欢迎您的访问!

This article is provided by a rotary feeder, and our website is: https://www.sdxinlujx.com We will provide you with wholehearted enthusiasm and welcome your visit!

- 上一篇: 负压气力输送如何保证落料均匀

- 下一篇: 负压气力输送

扫码微信沟通

扫码微信沟通