推荐消息更多>>

推荐消息更多>>负压除尘系统的构成要素有哪些?

- 来源:https://www.sdxinlujx.com/ 日期:2024-01-13 发布人:创始人

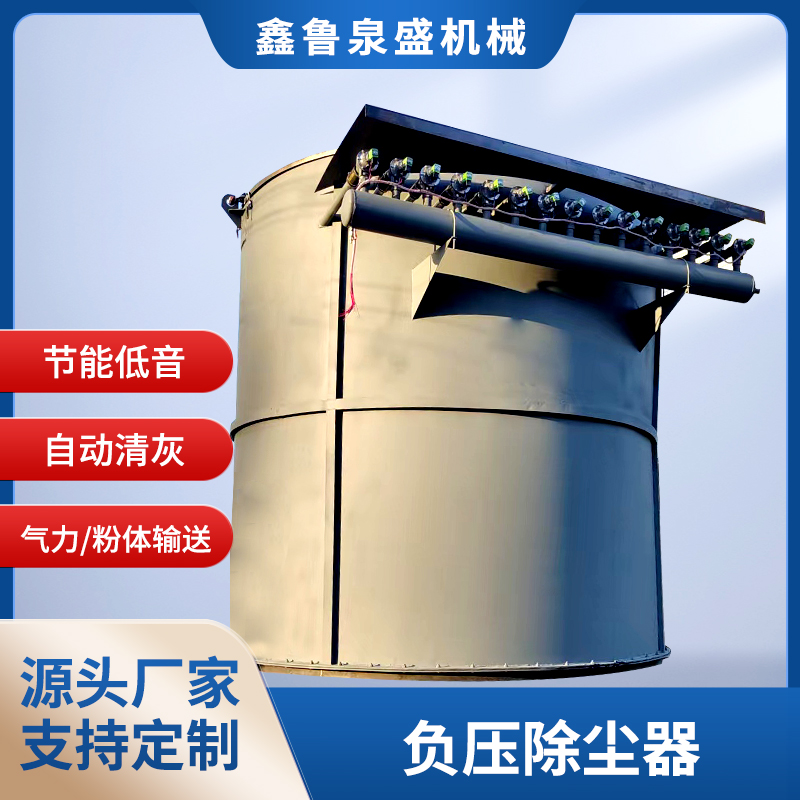

负压除尘系统是一种常见且有效的空气净化设备,通过产生负压环境,将空气中的固体颗粒物质吸入除尘设备,并净化后将空气排放出来。我们将深入探讨负压除尘系统的工作原理,包括负压的产生、过滤装置的作用和清灰系统的操作。此外,我们还将介绍负压除尘系统的构成要素,如风机、管道、过滤器等,并阐述它们在系统中的功能和作用。最后,我们将探讨负压除尘系统在工业、建筑、环保等领域中的广泛应用,并展望其未来的发展趋势

Negative pressure dust removal system is a common and effective air purification equipment. By creating a negative pressure environment, solid particulate matter in the air is sucked into the dust removal equipment, and after purification, the air is discharged. We will delve into the working principle of negative pressure dust removal systems, including the generation of negative pressure, the role of filtering devices, and the operation of dust removal systems. In addition, we will also introduce the constituent elements of the negative pressure dust removal system, such as fans, pipelines, filters, etc., and explain their functions and roles in the system. Finally, we will explore the widespread application of negative pressure dust removal systems in industries, buildings, environmental protection, and other fields, and look forward to their future development trends

概述负压除尘系统的背景和重要性。简要介绍固体颗粒物质对环境和健康的影响,以及负压除尘系统在净化空气方面的作用。

Overview of the background and importance of negative pressure dust removal systems. Briefly introduce the impact of solid particulate matter on the environment and health, as well as the role of negative pressure dust removal systems in purifying air.

第二部分:负压除尘系统的工作原理

Part 2: Working principle of negative pressure dust removal system

2.1 负压的产生 详细描述负压除尘系统中负压的产生机制。解释如何通过风机和管道系统建立负压环境,从而实现空气的吸入和排放。

2.1 Detailed description of negative pressure generation mechanism in negative pressure dust removal system. Explain how to establish a negative pressure environment through fans and piping systems to achieve air intake and discharge.

2.2 过滤装置的作用 探讨过滤装置在负压除尘系统中的重要性。介绍不同类型的过滤器,如袋式过滤器、滤筒过滤器等,以及它们如何有效地捕集和分离固体颗粒物质。

2.2 Discussion on the importance of filtration devices in negative pressure dust removal systems. Introduce different types of filters, such as bag filters, cartridge filters, etc., and how they effectively capture and separate solid particulate matter.

2.3 清灰系统的操作 阐述负压除尘系统中清灰系统的功能和操作原理。介绍不同的清灰方法,如机械振打清灰、气脉冲清灰等,以及如何清除积聚在过滤器上的粉尘。

2.3 Operation of Dust Cleaning System: Explain the functions and operating principles of the dust cleaning system in the negative pressure dust removal system. Introduce different cleaning methods, such as mechanical vibration cleaning, pulse cleaning, etc., as well as how to remove dust accumulated on the filter.

第三部分:负压除尘系统的构成要素

Part 3: Elements of Negative Pressure Dust Removal System

3.1 风机 详细介绍负压除尘系统中风机的作用和种类。解释如何通过风机产生负压,并保持系统中的空气流动。

3.1 Detailed introduction to the role and types of fans in negative pressure dust removal systems. Explain how to generate negative pressure through a fan and maintain air flow in the system.

3.2 管道系统 探讨负压除尘系统中管道系统的功能和布局。介绍管道的选择和设计,包括管道的材质、直径、长度等因素,以确保有效的气流传输和减少能量损失。

3.2 Pipeline System Discussion: The functions and layout of pipeline systems in negative pressure dust removal systems. Introduce the selection and design of pipelines, including factors such as material, diameter, length, etc., to ensure effective airflow transmission and reduce energy loss.

3.3 过滤器 阐述负压除尘系统中过滤器的类型和特点。介绍常见的过滤器材料,如纤维布、滤筒、活性炭等,以及其在捕集和分离固体颗粒物质方面的效果。

3.3 Filter Description: The types and characteristics of filters in negative pressure dust removal systems. Introduce common filter materials, such as fiber cloth, filter cartridges, activated carbon, etc., as well as their effectiveness in capturing and separating solid particulate matter.

3.4 集尘器 详细介绍负压除尘系统中集尘器的作用和种类。包括袋式集尘器、旋风集尘器、湿式集尘器等,解释它们如何收集和存储吸入的固体颗粒物质。

3.4 Detailed introduction to the function and types of dust collectors in negative pressure dust removal systems. Including bag type dust collectors, cyclone dust collectors, wet dust collectors, etc., explain how they collect and store inhaled solid particulate matter.

3.5 控制系统 探讨负压除尘系统中的控制系统的功能和重要性。解释如何通过传感器、控制器和自动化设备实现系统的监测、调节和操作。

3.5 Discussion on the Function and Importance of Control System in Negative Pressure Dust Removal System. Explain how to monitor, adjust, and operate the system through sensors, controllers, and automation equipment.

- 上一篇: 空气悬浮鼓风机出现变频器异常怎么处理?

- 下一篇: 负压组合除尘器工作原理

扫码微信沟通

扫码微信沟通