推荐消息更多>>

推荐消息更多>>负压气力输送与正压气力输送哪个更具有优势?

- 来源:https://www.sdxinlujx.com/ 日期:2024-08-12 发布人:创始人

负压气力输送与正压气力输送各有其独特的优势,具体哪个更具有优势取决于具体的应用场景和需求。

Negative pressure pneumatic conveying and positive pressure pneumatic conveying each have their unique advantages, and which one has more advantages depends on the specific application scenario and requirements.

负压气力输送的优势

The advantages of negative pressure pneumatic conveying

环保与安全:

Environmental Protection and Safety:

负压气力输送在管道内形成负压环境,有效防止了物料泄漏和粉尘飞扬,从而保护了工作环境和员工的身体健康。这对于处理有毒、有害或易燃易爆物料尤为重要。

Negative pressure pneumatic conveying creates a negative pressure environment inside the pipeline, effectively preventing material leakage and dust flying, thereby protecting the working environment and the health of employees. This is particularly important for handling toxic, harmful, or flammable and explosive materials.

系统采用密闭式输送,空气处理方便,适合于要求洁净空气输送的场合。

The system adopts a closed conveying system, which is convenient for air treatment and suitable for occasions that require clean air conveying.

适用范围广:

Wide applicability:

负压气力输送适用于散状物料、低洼处、破袋等输送场合,以及人工加料、多种出料口向一处集中输送等场景。

Negative pressure pneumatic conveying is suitable for conveying bulk materials, low-lying areas, broken bags, as well as scenarios such as manual feeding and centralized conveying of multiple discharge ports to one place.

它可以应用于多种行业,如化工、食品、医药等,对于需要防止物料污染或泄漏的场合特别适用。

It can be applied to various industries, such as chemical, food, pharmaceutical, etc., and is particularly suitable for situations that require prevention of material contamination or leakage.

能耗与成本:

Energy consumption and cost:

负压气力输送不需要消耗大量的能量来进行气体压缩,因此运行成本相对较低。

Negative pressure pneumatic conveying does not require a large amount of energy to compress gas, so the operating cost is relatively low.

但是,需要注意的是,如果工作真空度要求较高,可能会导致能耗增加。

However, it should be noted that if the working vacuum requirement is high, it may lead to an increase in energy consumption.

正压气力输送的优势

Advantages of positive pressure pneumatic conveying

输送距离与容量:

Conveying distance and capacity:

正压气力输送能够实现长距离、大容量的物料输送。正压稀相输送系统通常用于将散装物料从一个地点输送到一个或多个目的地,输送距离更长,容量更大。

Positive pressure pneumatic conveying can achieve long-distance and large capacity material transportation. Positive pressure dilute phase conveying systems are typically used to transport bulk materials from one location to one or more destinations, with longer conveying distances and larger capacities.

效率与自动化:

Efficiency and Automation:

正压气力输送系统具有较高的输送效率,可以实现物料的快速、连续输送。

The positive pressure pneumatic conveying system has high conveying efficiency and can achieve fast and continuous conveying of materials.

系统自动化程度高,减少了人工干预和操作难度,提高了生产效率。

The system has a high degree of automation, reducing manual intervention and operational difficulty, and improving production efficiency.

适应性与灵活性:

Adaptability and flexibility:

正压气力输送对物料的适应性较强,可以输送多种形态的物料,如颗粒、粉末等。

Positive pressure pneumatic conveying has strong adaptability to materials and can transport various forms of materials, such as particles, powders, etc.

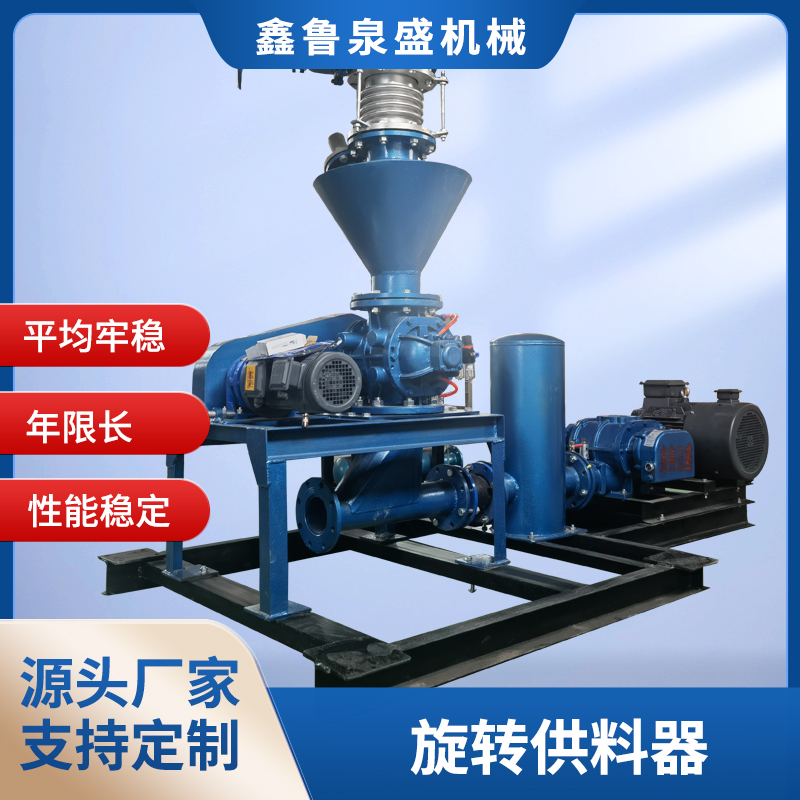

系统设计灵活,可以根据实际需求调整输送参数和供料装置,满足不同的生产需求。

The system design is flexible and can adjust the conveying parameters and feeding devices according to actual needs to meet different production requirements.

综合比较

general comparison

在环保与安全方面,负压气力输送具有明显优势,特别适合处理有毒、有害或易燃易爆物料。

In terms of environmental protection and safety, negative pressure pneumatic conveying has obvious advantages, especially suitable for handling toxic, harmful, or flammable and explosive materials.

在输送距离与容量方面,正压气力输送更具优势,适合长距离、大容量的物料输送需求。

In terms of conveying distance and capacity, positive pressure pneumatic conveying has more advantages and is suitable for long-distance and large capacity material conveying needs.

在能耗与成本方面,两者各有特点,需根据具体工作条件和要求进行评估。

In terms of energy consumption and cost, each has its own characteristics and needs to be evaluated based on specific working conditions and requirements.

在适应性与灵活性方面,两者都能满足多种物料的输送需求,但正压气力输送在系统设计上更为灵活。

In terms of adaptability and flexibility, both can meet the conveying needs of various materials, but positive pressure pneumatic conveying is more flexible in system design.

因此,无法一概而论地说哪个更具有优势,而是需要根据具体的应用场景和需求来选择适合的输送方式。在实际应用中,还需要综合考虑输送距离、输送量、物料特性、环保要求、成本效益等因素进行综合考虑和决策。

Therefore, it is not possible to generalize which one has more advantages, but it is necessary to choose the appropriate transportation method based on specific application scenarios and requirements. In practical applications, it is necessary to comprehensively consider and make decisions based on factors such as conveying distance, conveying volume, material characteristics, environmental requirements, cost-effectiveness, etc.

本文由负压气力输送友情奉献.更多有关的知识请点击:https://www.sdxinlujx.com真诚的态度.为您提供为全面的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from negative pressure pneumatic conveying. For more related knowledge, please click: https://www.sdxinlujx.com Sincere attitude. We provide you with comprehensive services. We will gradually contribute more relevant knowledge to everyone. Please stay tuned

- 上一篇: 罗茨鼓风机要不要试运行?

- 下一篇: 脉冲除尘器工作原理

扫码微信沟通

扫码微信沟通