推荐消息更多>>

推荐消息更多>>仓顶除尘器的风量确定需要考虑到多个因素

- 来源:https://www.sdxinlujx.com/ 日期:2023-10-27 发布人:admin

首先,风量的选择需要考虑到料仓的大小和储料能力。一般来说,料仓越大,储料能力越强,需要除尘的风量也就越大。因此,根据料仓的实际储量,可以选择适当的风量。

Firstly, the selection of air volume needs to consider the size and storage capacity of the silo. Generally speaking, the larger the silo, the stronger the storage capacity, and the greater the air volume required for dust removal. Therefore, based on the actual storage capacity of the silo, an appropriate air volume can be selected.

其次,确定仓中上料的打料形式也是重要的。仓中上料的打料形式有气体打入和机械带入两种。如果采用机械带入的方式,自然需要选择较小的烟气量,因为这种方式产生的尘土量较小。而如果采用气体打入的方式,则可以选择较大的烟气量,因为这种方式产生的尘土量较大。

Secondly, it is also important to determine the form of feeding in the warehouse. There are two forms of feeding in the warehouse: gas injection and mechanical injection. If mechanical entry is used, it is naturally necessary to choose a smaller amount of smoke, as this method produces a smaller amount of dust. If gas injection is used, a larger amount of smoke can be chosen, as this method generates a larger amount of dust.

此外,物料的比重和颗粒力度的比例关系也是需要考虑的因素。如果物料的比重较大或颗粒力度较高,那么需要选择较大的风量,以更好地清除这些物料产生的尘土。

In addition, the proportion relationship between the specific gravity of the material and the particle strength also needs to be considered. If the specific gravity of the material is high or the particle strength is high, it is necessary to choose a larger air volume to better remove the dust generated by these materials.

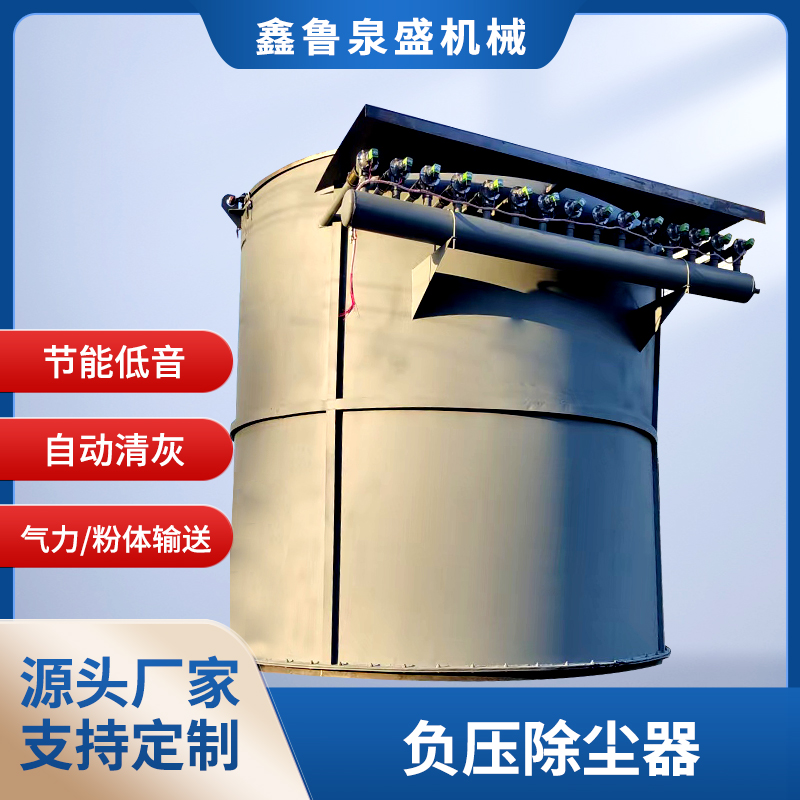

另外,确定除尘器的除尘效率和处理风量范围也是关键的一步。可以参考行业标准或厂家提供的数据来进行这一步骤。然后,计算所需处理风量,即所需处理颗粒物总量除以罐仓内空气流通时间。最后,根据计算结果选择符合要求的除尘器型号和规格。

In addition, determining the dust removal efficiency and processing air volume range of the dust collector is also a crucial step. You can refer to industry standards or data provided by manufacturers for this step. Then, calculate the required processing air volume, which is the total amount of particulate matter required to be processed divided by the air circulation time inside the tank. Finally, select the dust collector model and specifications that meet the requirements based on the calculation results.

需要注意的是,除尘器风量过大会造成能源浪费和设备不稳定等问题,而风量过小则会影响除尘效果和生产效率等方面。因此,在选择风量时需要进行科学计算和合理评估,确保所选设备符合实际情况和需求。

It should be noted that excessive air volume in the dust collector can cause energy waste and equipment instability, while low air volume can affect dust removal efficiency and production efficiency. Therefore, scientific calculation and reasonable evaluation are necessary when selecting air volume to ensure that the selected equipment meets the actual situation and needs.

- 上一篇: 一套稀相粉体气力输送系统中包含哪些设备?

- 下一篇: 工业制冷中使用的三叶罗茨风机的优势特点

扫码微信沟通

扫码微信沟通