推荐消息更多>>

推荐消息更多>>锅炉布袋除尘器的正压和负压式除尘的效果区别

- 来源:https://www.sdxinlujx.com/ 日期:2023-10-09 发布人:admin

锅炉布袋除尘器从而被更多的人认识和应用,也就是说在锅炉行业,锅炉布袋除尘器是必须要求上的。由于锅炉布袋除尘器的不同分类方法,可以分成许多类型,从而用于不同粉尘和不同的企业工况条件。下面就讲一下,按照锅炉布袋除尘器的工作状态来分类。除尘器可分为正压除尘器和负压除尘器两大类。按其工作温度,可分为两大类:常温除尘器和高温除尘器。按除尘器的大小可分为四大类:小型除尘器、中型除尘器、大型除尘器及超大型除尘器等。

The boiler bag filter has been recognized and applied by more people, which means that in the boiler industry, the boiler bag filter is a necessary requirement. Due to the different classification methods of boiler bag filters, they can be divided into many types and can be used for different dust and enterprise operating conditions. Let's talk about the classification based on the working status of boiler bag filters. Dust collectors can be divided into two categories: positive pressure dust collectors and negative pressure dust collectors. According to its working temperature, it can be divided into two categories: room temperature dust collectors and high-temperature dust collectors. According to the size of dust collectors, they can be divided into four categories: small dust collectors, medium dust collectors, large dust collectors, and super large dust collectors.

现在我们详细讲解一下锅炉布袋除尘器的正压和负压式除尘的区别及效果

Now let's explain in detail the differences and effects of positive pressure and negative pressure dust removal in boiler bag filters、

正压式锅炉布袋除尘器:风机设置在除尘器之前,除尘器在正压状态下工作。由于含尘气体先经过风机,对风机的磨损较严重,因此不适用于高浓度、粗颗粒、高硬度、强腐蚀性的粉尘。

Positive pressure boiler bag dust collector: The fan is set before the dust collector, and the dust collector operates under positive pressure. Due to the fact that dusty gases first pass through the fan and cause severe wear on the fan, they are not suitable for high concentration, coarse particles, high hardness, and strong corrosive dust.

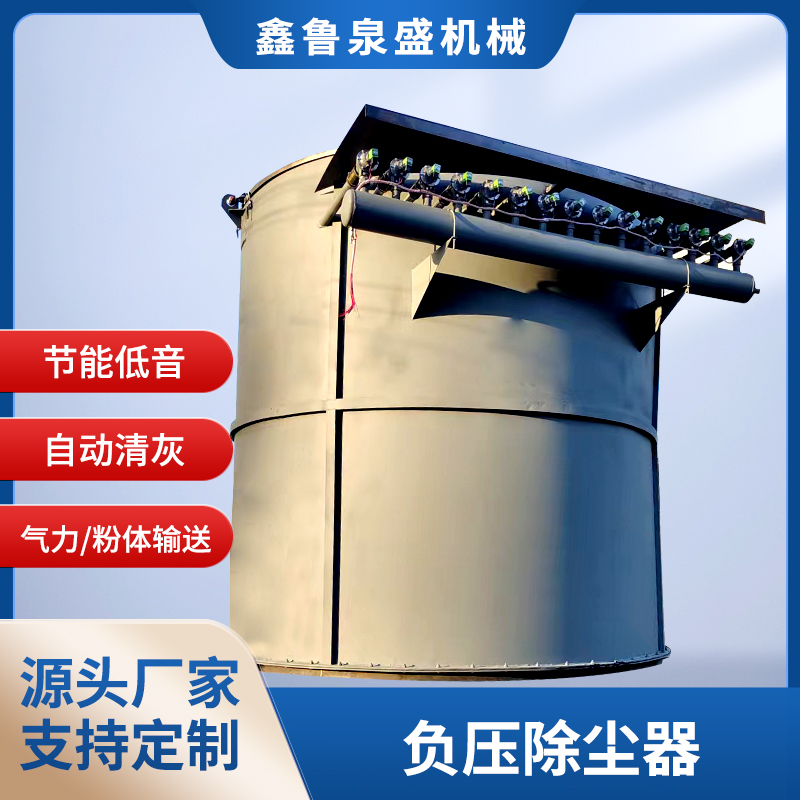

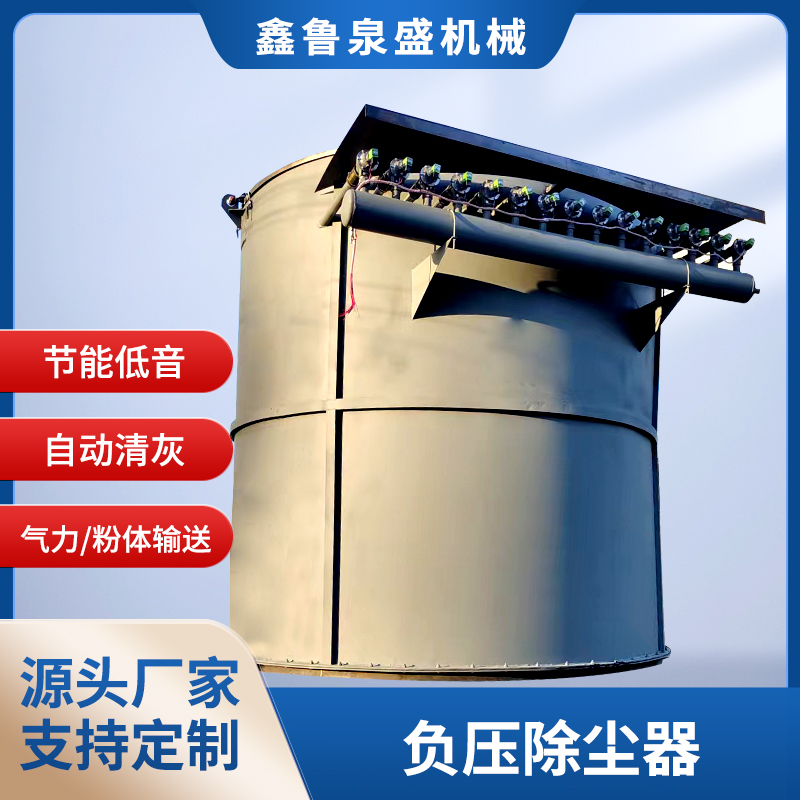

负压式锅炉布袋除尘器:风机置于除尘器之后,除尘器在负压状态下工作,由于含尘气体经净化后在进入风机,因此对风机的磨损较小,这种方式采用较多。

Negative pressure boiler bag dust collector: The fan is placed behind the dust collector, and the dust collector operates in a negative pressure state. Due to the purified dust containing gas entering the fan, the wear on the fan is relatively small, and this method is commonly used.

而对于锅炉除尘的复杂性,单单依靠一种类型的除尘器亦不能达到要求,所以,在提高除尘效率的前提下,有的企业单位就会设置多级除尘:在前级设粗颗粒除尘装置,后级设细颗粒除尘装置的各类串联组合式除尘装置。比如在锅炉布袋除尘器前加一级二级脱硫设备,加降温除尘设备等,或有的需加旋风除尘设备等。

For the complexity of boiler dust removal, relying solely on one type of dust collector cannot meet the requirements. Therefore, in order to improve dust removal efficiency, some enterprise units will set up multi-level dust removal: various series combination dust removal devices with coarse particle dust removal devices in the front stage and fine particle dust removal devices in the rear stage. For example, adding primary and secondary desulfurization equipment, cooling and dust removal equipment, or some requiring cyclone dust removal equipment in front of the boiler bag filter.

- 上一篇: 三叶罗茨风机相比双叶有哪些优势特点?

- 下一篇: 粉体输送系统中输送管道设计要注意什么?

Related news相关新闻

- 2025-10-25磁悬浮鼓风机:节能环保高效的气体输送设备

- 2025-10-24气力输送系统输送时物料易破碎怎么办?

- 2025-10-23旋转供料器在粉体输送中发挥中锁风下料、定量吹送的作用

- 2025-10-22仓泵在气力输送“心脏”中,扮演着重要角色

- 2025-10-21负压气力输送适合输送哪些类型的物料?

- 2025-10-20安全使用高压罗茨鼓风机必须要注意的8个方面

- 2025-10-18三叶罗茨风机经过频繁检修后,整理的常见故障原因和解决方法

- 2025-10-17高压罗茨鼓风机节能省电的方法和运行中的摩擦原因

- 2025-10-16高压罗茨风机 VS 离心风机,区别有哪些?

- 2025-10-15高压罗茨风机的产品介绍和适用场景

扫码微信沟通

扫码微信沟通