推荐消息更多>>

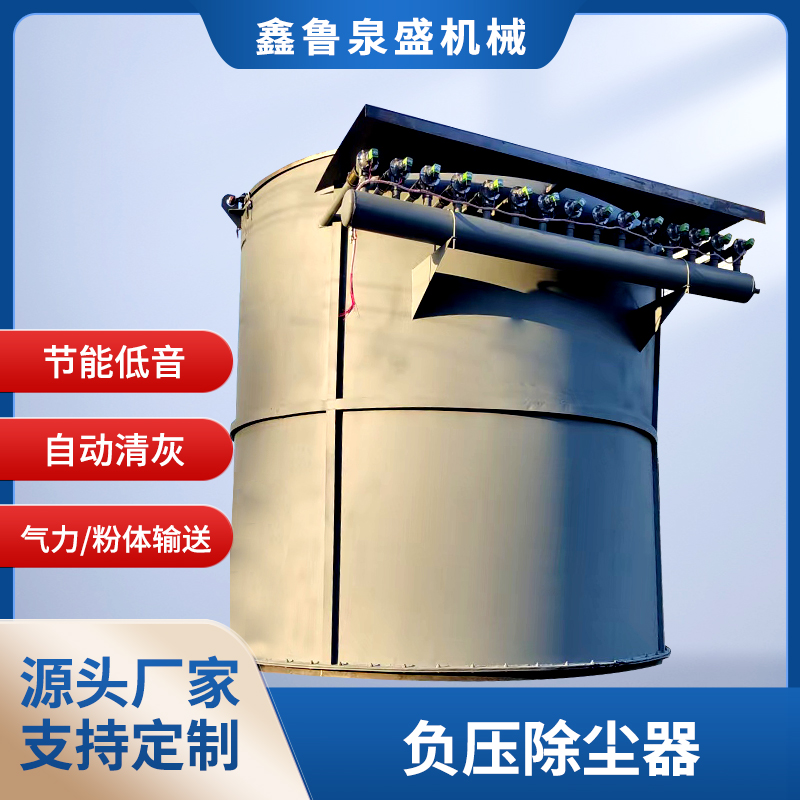

推荐消息更多>>负压除尘器在使用中的工作原理

- 来源:https://www.sdxinlujx.com/ 日期:2023-11-08 发布人:admin

负压除尘器主要依靠设备内部的负压环境实现除尘。当含尘空气经过负压除尘器时,空气在负压作用下被迅速吸入除尘器内,尘粒在负压作用下被吸附在除尘器内壁上,而清洁空气则通过除尘器顶部排出。相较于传统的正压除尘器,负压除尘器具有更高的除尘效率和更低的能耗。

The negative pressure dust collector mainly relies on the negative pressure environment inside the equipment to achieve dust removal. When dusty air passes through the negative pressure dust collector, the air is quickly sucked into the dust collector under the negative pressure, and dust particles are adsorbed on the inner wall of the dust collector under the negative pressure, while clean air is discharged through the top of the dust collector. Compared to traditional positive pressure dust collectors, negative pressure dust collectors have higher dust removal efficiency and lower energy consumption.

负压除尘器的设计原理简单但G效。其主要由吸尘管、过滤室、旋风分离器、集尘箱、引风机等部分组成。在负压除尘器的运行过程中,引风机产生的负压使得含尘空气进入吸尘管,随后进入过滤室。在过滤室内,大颗粒粉尘由于重力作用落入集尘箱,而细小粉尘则随气流进入旋风分离器。在旋风分离器中,细小粉尘受到离心力作用被甩向器壁,随后落入集尘箱。

The design principle of negative pressure dust collector is simple but G-efficient. It mainly consists of vacuum pipes, filter chambers, cyclone separators, dust collection boxes, induced draft fans, and other parts. During the operation of the negative pressure dust collector, the negative pressure generated by the induced draft fan causes dusty air to enter the suction pipe and then enter the filter room. In the filtering room, large particles of dust fall into the dust collection box due to gravity, while small particles enter the cyclone separator with the airflow. In a cyclone separator, fine dust is thrown towards the wall by centrifugal force and then falls into the dust collection box.

负压除尘器的应用领域十分广泛,如矿业、化工、医药、食品加工、冶金等行业的生产车间和实验室。在这些场所中,由于生产过程或实验过程中产生的粉尘会对环境和人体健康造成危害,因此需要采取有效的除尘措施。负压除尘器的出现为这些行业提供了新的解决方案。

The application fields of negative pressure dust collectors are very extensive, such as production workshops and laboratories in industries such as mining, chemical, pharmaceutical, food processing, metallurgy, etc. In these places, effective dust removal measures need to be taken due to the harmful effects of dust generated during production or experimental processes on the environment and human health. The emergence of negative pressure dust collectors provides new solutions for these industries.

以某矿业企业为例,该企业采用负压除尘器进行矿料粉碎工序的粉尘治理。在生产过程中,矿料粉尘在负压作用下被迅速吸入除尘器内,经过G效过滤和分离后,清洁空气排出,而粉尘则被收集在集尘箱中方便后续处理。

Taking a mining enterprise as an example, it uses a negative pressure dust collector for dust control in the ore crushing process. During the production process, mineral dust is quickly sucked into the dust collector under negative pressure, and after being filtered and separated by G-effect, clean air is discharged. The dust is collected in a dust collection box for subsequent processing.

负压除尘器的出现为工业生产带来了诸多好处。首先,其G效率的除尘效果降低了企业对于环保设备的投入成本。其次,负压除尘器的低能耗设计为企业节省了大量能源。此外,负压除尘器的维护成本较低,为企业降低了运营压力。

The emergence of negative pressure dust collectors has brought many benefits to industrial production. Firstly, the dust removal effect of its G efficiency reduces the investment cost of environmental protection equipment for enterprises. Secondly, the low energy consumption design of negative pressure dust collectors saves a lot of energy for enterprises. In addition, the maintenance cost of negative pressure dust collectors is relatively low, which reduces operational pressure for enterprises.

本文由负压组合除尘器为您提供,我们的网站是:http://www.sdxinlujx.com我们将以全心全意的热情为您提供服务,欢迎您的访问!

This article is provided by the negative pressure combination dust collector, and our website is: http://www.sdxinlujx.com We will provide you with wholehearted enthusiasm and welcome your visit!

- 上一篇: 负压真空上料机的工作原理及特点介绍

- 下一篇: 高压水冷罗茨风机的使用功能介绍

Related news相关新闻

- 2025-10-25磁悬浮鼓风机:节能环保高效的气体输送设备

- 2025-10-24气力输送系统输送时物料易破碎怎么办?

- 2025-10-23旋转供料器在粉体输送中发挥中锁风下料、定量吹送的作用

- 2025-10-22仓泵在气力输送“心脏”中,扮演着重要角色

- 2025-10-21负压气力输送适合输送哪些类型的物料?

- 2025-10-20安全使用高压罗茨鼓风机必须要注意的8个方面

- 2025-10-18三叶罗茨风机经过频繁检修后,整理的常见故障原因和解决方法

- 2025-10-17高压罗茨鼓风机节能省电的方法和运行中的摩擦原因

- 2025-10-16高压罗茨风机 VS 离心风机,区别有哪些?

- 2025-10-15高压罗茨风机的产品介绍和适用场景

扫码微信沟通

扫码微信沟通